Low price Right Horizontal Paddle Mixer

Our Right Horizontal Paddle Mixer is engineered to deliver the best results at a low price, ensuring that you receive a cost-effective solution without compromising on quality. With discounts available for bulk purchases, you can enjoy wholesale prices on a top-quality machine that guarantees optimal mixing efficiency. Our factory-direct products are manufactured to the highest standards, ensuring durability and reliability in your production processes.

- Performance Introduction

- Video

- Case

- Main parameters and advantages

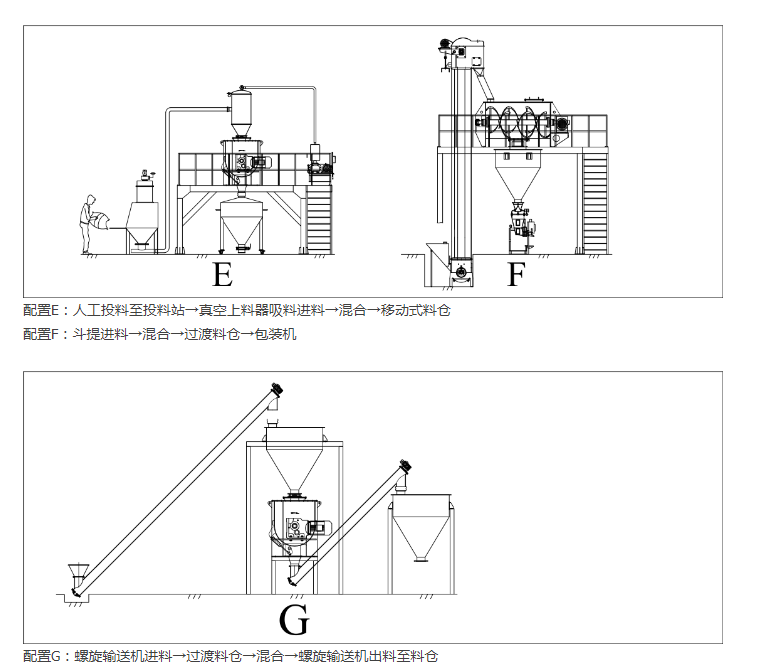

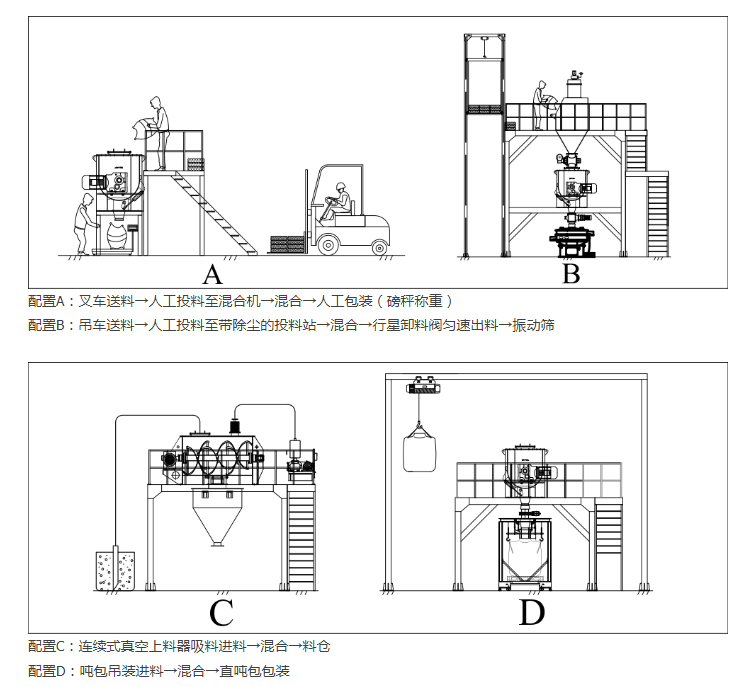

- Configuration Description

- Workflow diagram

-

- Commodity name: Low price Right Horizontal Paddle Mixer

Our Right Horizontal Paddle Mixer is engineered to deliver the best results at a low price, ensuring that you receive a cost-effective solution without compromising on quality. With discounts available for bulk purchases, you can enjoy wholesale prices on a top-quality machine that guarantees optimal mixing efficiency. Our factory-direct products are manufactured to the highest standards, ensuring durability and reliability in your production processes.

Brief description:

Looking for the best Right Horizontal Paddle Mixer in China that offers good price and quality? You're in the right place! Our company specializes in providing customized mixing solutions that are tailored to meet your specific requirements. As one of the top manufacturers in China, we offer a diverse range of mixing equipment, including the Right Horizontal Paddle Mixer, known for its exceptional performance and versatility in blending various materials.

Our Right Horizontal Paddle Mixer is engineered to deliver the best results at a low price, ensuring that you receive a cost-effective solution without compromising on quality. With discounts available for bulk purchases, you can enjoy wholesale prices on a top-quality machine that guarantees optimal mixing efficiency. Our factory-direct products are manufactured to the highest standards, ensuring durability and reliability in your production processes.

When you choose our company as your supplier, you can expect superior products and outstanding customer service. We are dedicated to providing the best mixing solutions to suit your production needs, offering a range of options to accommodate different materials and applications. Count on our team of experienced manufacturers and suppliers to deliver reliable mixing equipment that enhances your operational efficiency.

Contact us today to discover more about our Right Horizontal Paddle Mixer and take advantage of the best wholesale prices available in China. Experience the benefits of a customized mixing solution that integrates quality, efficiency, and affordability,making it the ideal choice for your mixing requirements. -

-

-

Model

NSJ-300

NSJ-500

NSJ-1000

NSJ-1500

NSJ-2000

NSJ-3000

effective volume

300L

500L

1000L

1500L

2000L

3000L

Loading factor

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

Speed

53rpm

53rpm

45rpm

45rpm

39rpm

39rpm

Weight of whole machine

660kg

900kg

1380kg

1850kg

2350kg

2900kg

Overall power

5.5kw

7.5kw

11kw

15kw

18.5kw

22kw

Total length

1330

1480

1730

2030

2120

2420

Total width

1130

1350

1590

1740

2000

2300

Total height

1030

1220

1380

1480

1630

1780

Barrel radius/R

277

307

377

450

485

534

Power

3P AC208-415v 50/60Hz

-

Material selection scheme

1. Mixer can be usedA variety of stainless steel,201Stainless steel,304Stainless Steeland316Stainless SteelDistinction:

2. Contact with materials and non-contact with materials;

3. The stainless steel surface treatment is divided into sandblasting, wire drawing, polishing, mirror and other treatment methods, and can be applied to different parts of use;

Drive Configuration

1. The mixer is equipped with driving devices with different capacities, different powers and different output speeds according to the nature of the material, the starting mode and the stirring mode.

2. The selection of driving motor includes: ordinary motor, anti-riot motor, variable frequency motor, high efficiency and energy saving motor, high protection grade motor, and motor under different voltage;

3. Commonly used reducer:R, K, F series gear reducer, cycloid reducer, universal gear reducer, planetary gear reducer;

4. Common connection methods: direct connection, pulley connection, hydraulic coupling connection.

discharge device

1. HorizontalTapeThe mixer is conventionally equipped with a pneumatic curved flap valve. When the valve is closed, the curved flap of the valve completely fits the arc surface of the cylinder. During the mixing process, there is no excess mixing dead angle, so that the mixed material is more uniform.

2, the valve drive can be distinguished as manual, pneumatic, electric three. Valves for reference include powder spherical valve, roller valve, plum blossom dislocation valve, powder butterfly valve, rotary feeding valve, etc.

-

Previous Page

Next Page

Previous Page

Next Page

Related Products