Single paddle mixer

Single blade mixer, suitable for particles and powder, particles and particles, and add a small amount of liquid mixing, widely used in nuts, beans, feed, and other granular materials. There are paddles with different angles inside the machine to throw up the materials so as to cross-mix them and achieve the effect of fast mixing and uniformity.

- Performance Introduction

- Video

- Case

- Main parameters and advantages

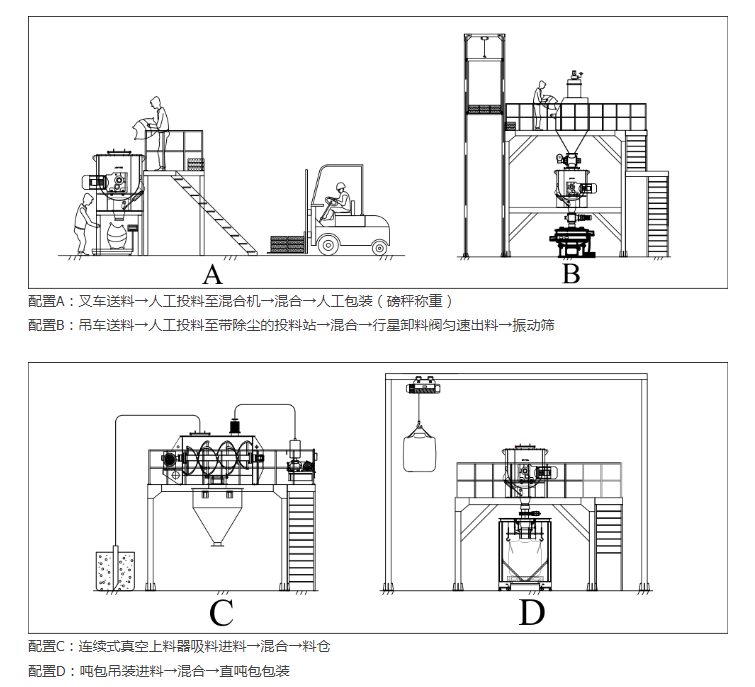

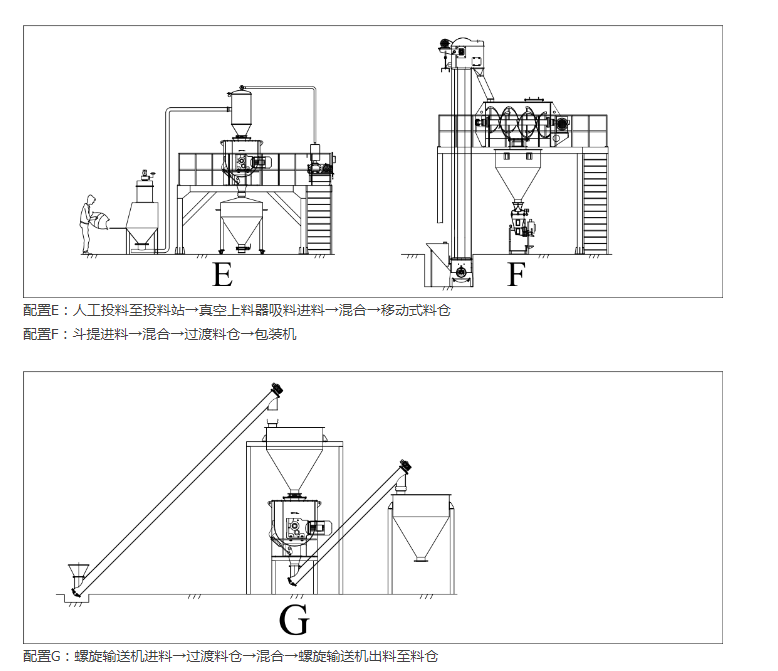

- Configuration Description

- Workflow diagram

-

- Commodity name: Single paddle mixer

Single blade mixer, suitable for particles and powder, particles and particles, and add a small amount of liquid mixing, widely used in nuts, beans, feed, and other granular materials. There are paddles with different angles inside the machine to throw up the materials so as to cross-mix them and achieve the effect of fast mixing and uniformity.

Brief description:

Single blade mixer, suitable for particles and powder, particles and particles, and add a small amount of liquid mixing, widely used in nuts, beans, feed, and other granular materials. There are paddles with different angles inside the machine to throw up the materials so as to cross-mix them and achieve the effect of fast mixing and uniformity.

Key features:

1. Blades in different directions drive the material to be thrown at different angles, and the mixing time is 5-10 minutes;

2. The compact design makes the whole bin body full when the blade rotates, and the mixing uniformity is as high as 95%;

3. The gap between the blade and the barrel body is 1-3mm, and the open discharge port;

4. Patented design ensures zero leakage of rotating shaft and discharge port;

5. The mixing bin is fully welded and polished, without any screws, nuts and other fasteners;

6. Except for the bearing seat, the other parts of the whole machine are all made of stainless steel, which is exquisite and generous.

7. Full volume of equipment: 100L-10000L

8. Maximum loading coefficient of equipment: 0.8

-

-

-

Model/Model

NDJ-200L

NDJ-300L

NDJ-500L

NDJ-1000L

NDJ-1500L

NDJ-2000L

NDJ-3000L

effective capacity

200L

300L

500L

1000L

1500L

2000L

3000L

Loading factor

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

0.6-0.8

Speed

53rpm

53rpm

45rpm

45rpm

39rpm

39rpm

39rpm

Weight of whole machine

450kg

650kg

980kg

1300kg

1600kg

2200kg

2600kg

Overall power

4kw

5.5kw

7.5kw

11kw

15kw

18.5kw

22kw

Total length

1800

1900

2050

2500

2950

3300

3350

Total width

900

1000

1050

1200

1350

1550

1880

Total height

1100

1200

1250

1500

1650

1750

1950

Power

3P AC208-415V 50/60HZ

-

Material selection scheme

1. Mixer can be usedA variety of stainless steel,201Stainless steel,304Stainless Steeland316Stainless SteelDistinction:

2. Contact with materials and non-contact with materials;

3. The stainless steel surface treatment is divided into sandblasting, wire drawing, polishing, mirror and other treatment methods, and can be applied to different parts of use;

Drive Configuration

1. The mixer is equipped with driving devices with different capacities, different powers and different output speeds according to the nature of the material, the starting mode and the stirring mode.

2. The selection of driving motor includes: ordinary motor, anti-riot motor, variable frequency motor, high efficiency and energy saving motor, high protection grade motor, and motor under different voltage;

3. Commonly used reducer:R, K, F series gear reducer, cycloid reducer, universal gear reducer, planetary gear reducer;

4. Common connection methods: direct connection, pulley connection, hydraulic coupling connection.

discharge device

1. HorizontalTapeThe mixer is conventionally equipped with a pneumatic curved flap valve. When the valve is closed, the curved flap of the valve completely fits the arc surface of the cylinder. During the mixing process, there is no excess mixing dead angle, so that the mixed material is more uniform.

2, the valve drive can be distinguished as manual, pneumatic, electric three. Valves for reference include powder spherical valve, roller valve, plum blossom dislocation valve, powder butterfly valve, rotary feeding valve, etc.

-

Previous Page

Next Page

Previous Page

Next Page

Related Products