Bucket elevator

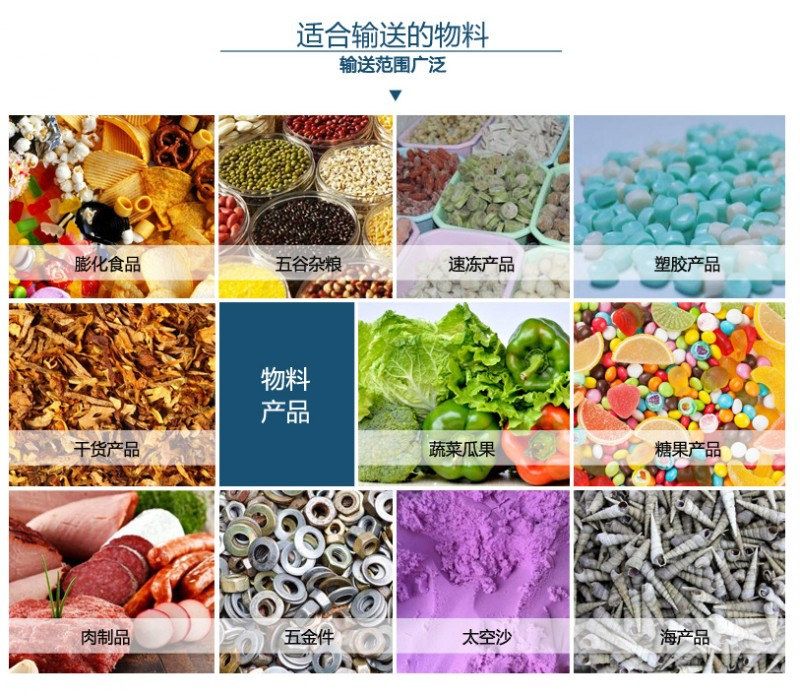

The Z-type bucket elevator is suitable for lifting from low to high. After the supplied materials are put into the hopper through the vibration table, the machine automatically and continuously runs and transports upward. The conveying speed can be adjusted according to the conveying amount, and the lifting height can be selected as required. The hopper is designed and manufactured by itself. PP nontoxic hopper makes this type of bucket elevator more widely used. All sizes are designed and manufactured according to actual needs. It is designed for supporting vertical packaging machines and computer metering machines. It is suitable for lifting and feeding food, medicine, chemical industrial products, screws, nuts and other products. The automatic shutdown of the machine can be controlled through signal recognition of the packaging machine.

- Performance Introduction

- Main advantages

- Video

- Case

- Main parameters

-

- Commodity name: Bucket elevator

The Z-type bucket elevator is suitable for lifting from low to high. After the supplied materials are put into the hopper through the vibration table, the machine automatically and continuously runs and transports upward. The conveying speed can be adjusted according to the conveying amount, and the lifting height can be selected as required. The hopper is designed and manufactured by itself. PP nontoxic hopper makes this type of bucket elevator more widely used. All sizes are designed and manufactured according to actual needs. It is designed for supporting vertical packaging machines and computer metering machines. It is suitable for lifting and feeding food, medicine, chemical industrial products, screws, nuts and other products. The automatic shutdown of the machine can be controlled through signal recognition of the packaging machine.

The type bucket elevator is suitable for lifting from low to high. After the supplied materials are put into the hopper through the vibration table, the machine automatically and continuously runs and transports upward. The conveying speed can be adjusted according to the conveying amount, and the lifting height can be selected as required. The hopper is designed and manufactured by itself. PP nontoxic hopper makes this type of bucket elevator more widely used. All sizes are designed and manufactured according to actual needs. It is designed for supporting vertical packaging machines and computer metering machines. It is suitable for lifting and feeding food, medicine, chemical industrial products, screws, nuts and other products. The automatic shutdown of the machine can be controlled through signal recognition of the packaging machine.

-

1. Each adjacent hopper is connected to each other with rubber connecting strips, without gaps and material leakage.

2、The transmission capacity can reach 30 cubic meters/hour.

3. The box-type structure can isolate external pollution, and there are no dead corners inside the machine and no hidden materials.

4. The conveyed material falls from the hopper by gravity, avoiding the damage of the material.

5. Using rubber chain, silent operation, maintenance-free, inelastic, no need to add lubricating oil, non-corrosive, strong wear resistance.

-

Previous Page

Next Page

Previous Page

Next Page

Related Products