Automatic batching and packaging system complete

Release time:

2024-01-12 15:32

Source:

Automatic batching and packaging system complete

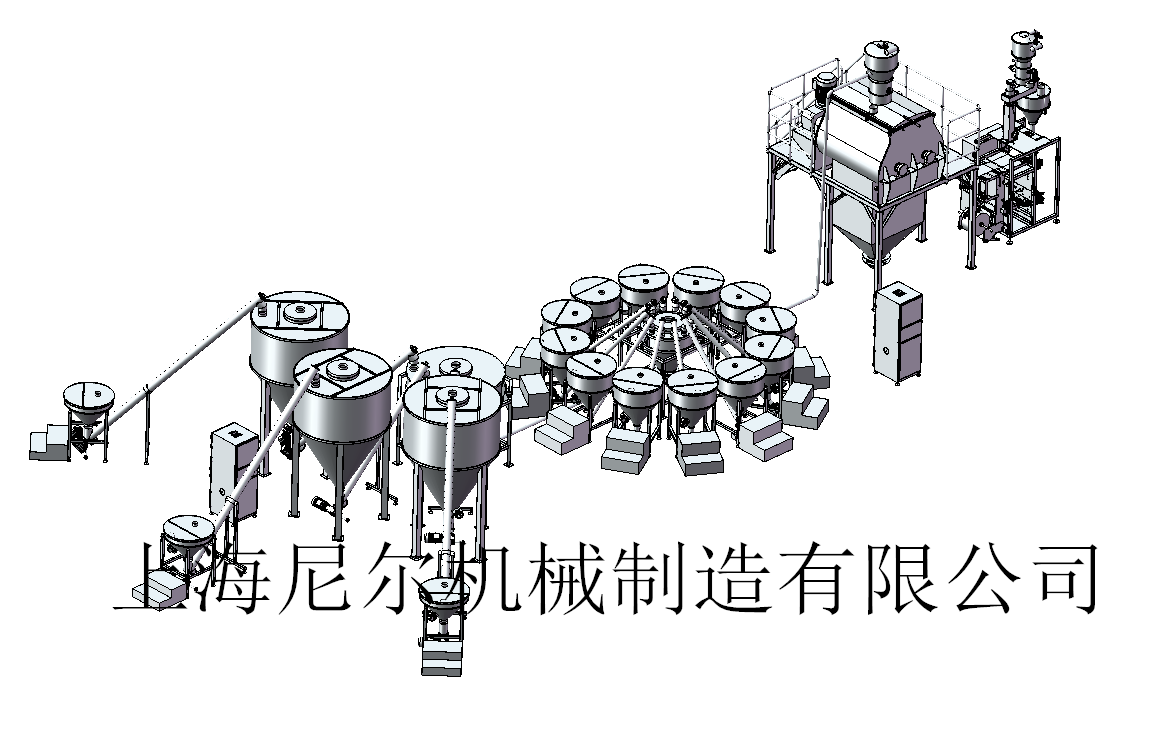

Recently, Neil Machinery's multi-material handling packaging system has been installed and commissioned in the customer's factory. The production line is suitable for food industry, chemical industry and other fields. It is mainly used for processing products with complex formulations. It takes 7 weeks for the design, processing and packaging of the production line, and provides customers with on-site installation and training for free

The system is used to handle the mixing and packaging of complex materials. The system mainly mixes two processed materials. The storage bin 1 is the raw material of the first material, and the storage bin 2 is the raw material of the second material.

The detailed workflow is as follows:

The first three silos of storage bin 1 start feeding to the fourth silo. The fourth silo is equipped with an automatic weighing system. After the silo is over, the feeding will be stopped, and then the vacuum conveyor above the mixer will suck the material from the fourth silo into the mixer.

2. Storage bin 2 is 12 small silos. In the middle there is a large silo with an automatic weighing system. After the materials of the 12 small silos enter the intermediate silo according to a certain proportion, the feeding will be stopped., Then the vacuum conveyor above the mixer sucks the material from the intermediate silo into the mixer

3. The mixer mixes the two materials, and then discharges the mixed materials into the silo at the bottom.

4. The vacuum conveyor on the top of the packaging machine sucks the materials in the pressure regulating bin into the storage box of the packaging machine, and then the packaging machine starts to pack the materials.

Related News

Boosting Efficiency: Semi Automatic Powder Filling Machine in Action

Boosting Efficiency: Semi Automatic Powder Filling Machine in Action Table of Contents 1. Introduction to Semi Automatic Powder Filling Machines 2. What is a Semi Automatic Powder Filling Machine? 3. How Does a Semi Automatic Powder Filling Machine Work? 4. Benefits of Semi Automatic Powder Filling Machines 5. Applications of Semi Automatic Powder Filling Machines 6. Maint

Understanding Semi-Automatic Powder Filling Machines: A Comprehensive Overview

Semi-automatic powder filling machines are pivotal in the packaging sector, particularly for businesses handling powdered products such as spices, flour, chemicals, and pharmaceuticals. These machines bridge the gap between manual filling methods and fully automatic systems, offering businesses an optimal solution for efficiency and precision. One of the primary advantages of semi-automatic powder

The Evolution of Mixing Machinery: Horizontal Paddle Mixers at the Forefront

The Evolution of Mixing Machinery: Horizontal Paddle Mixers at the Forefront Table of Contents 1. Introduction to Mixing Machinery 2. A Brief History of Mixing Machinery 3. Technological Advancements in Mixing Machinery 4. Understanding Horizontal Paddle Mixers 5. Applications of Horizontal Paddle Mixers 6. Advantages of Horizontal Paddle Mixers 7. The Future of Mixing Machinery 8

The Essential Guide to Horizontal Paddle Mixers: Applications and Benefits

Horizontal paddle mixers are vital components in various manufacturing and processing operations, particularly within the realm of mixing machinery. Understanding the workings and benefits of these mixers can significantly enhance operational efficiency and product quality. A horizontal paddle mixer typically features a cylindrical mixing chamber equipped with paddles that rotate on a horizontal a

Exploring the Dynamic Capabilities of Industrial Ribbon Mixers Table of Contents Introduction to Industrial Ribbon Mixers Understanding the Mechanics of Ribbon Mixers Advantages of Using Ribbon Mixers in Manufacturing Applications of Ribbon Mixers Across Industries Maintaining Your Ribbon Mixer for Longevity Future Trends in Ribbon Mixer Technology Case Studies: Ribbon Mixers in Act

Understanding Industrial Ribbon Mixers: Essential Tools for Effective Material Blending

Industrial ribbon mixers are vital pieces of equipment used in various manufacturing processes, particularly in the blending of powdered and granular materials. These mixers are characterized by their unique design, featuring a set of helical ribbons that move materials through the mixing chamber, ensuring a thorough and uniform blend. With increasing demands for consistency and quality in product