Fuyi Cang Rice Food Mixed Conveying Production Line Successfully Installed and Debugged

Release time:

2024-01-12 15:30

Source:

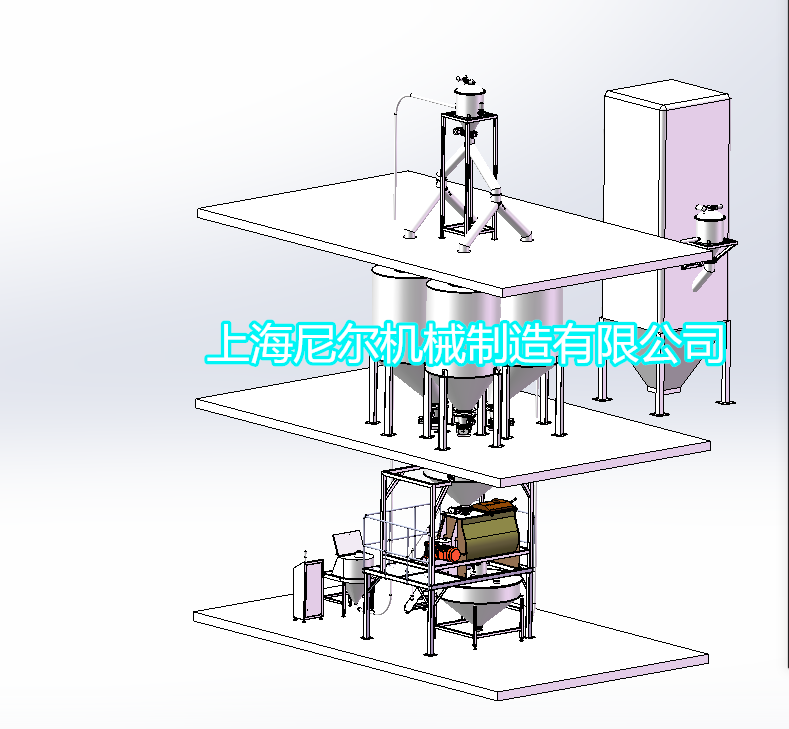

On November 20, 2019, Shanghai Neil Machinery Manufacturing Co., Ltd. completed a non-standard customized 5000L production line for rice mixed conveying packaging. The factory belongs to the old floor, with a height of only 3.5 meters and a small floor area. Our company sent a team to inspect the site and communicate with each other. After three detailed communications, we finally reached an agreement on the scheme of rice horizontal powder production line.

Main equipment of rice horizontal powder production line:

1. Feeding platform

2. Vacuum feeder

3. Storage Silo NCL-5000L

4. Weighing storage bin 5000L

5. Single blade mixer NDJ-3000L

6. Working platform

7. Irregular storage bin 3000L

8. Complete control system

The main difficulty of this horizontal rice powder production line is that the floor is low. We need to control the height. The vacuum conveyor needs long-distance Z-type transportation. The pressure of the vacuum conveyor is high, and the coordination degree of each set of equipment is high. It must be seamlessly connected. The storage silo is large, from the first floor to the third floor, the installation is difficult, and the wire and pipeline layout is difficult. However, after a week of installation and commissioning, these problems were solved by our professional installers.

Shanghai Neil Machinery Manufacturing Co., Ltd. has been committed to the processing, production and R & D design of food horizontal powder production line, conveyor, packaging machine, dust removal machine, vacuum and spiral feeding machine, weight selection and inspection scale and other equipment and related supporting products. Companies adhering to the business philosophy of quality and service, dedicated to provide our customers with quality products and services, and strive to provide our customers with zero trouble products, do our best to meet the needs of our customers. Customer service, customer achievement, sincerely look forward to working with new and old customers hand in hand, side by side, create a better tomorrow.

Related News

Boosting Efficiency: Semi Automatic Powder Filling Machine in Action

Boosting Efficiency: Semi Automatic Powder Filling Machine in Action Table of Contents 1. Introduction to Semi Automatic Powder Filling Machines 2. What is a Semi Automatic Powder Filling Machine? 3. How Does a Semi Automatic Powder Filling Machine Work? 4. Benefits of Semi Automatic Powder Filling Machines 5. Applications of Semi Automatic Powder Filling Machines 6. Maint

Understanding Semi-Automatic Powder Filling Machines: A Comprehensive Overview

Semi-automatic powder filling machines are pivotal in the packaging sector, particularly for businesses handling powdered products such as spices, flour, chemicals, and pharmaceuticals. These machines bridge the gap between manual filling methods and fully automatic systems, offering businesses an optimal solution for efficiency and precision. One of the primary advantages of semi-automatic powder

The Evolution of Mixing Machinery: Horizontal Paddle Mixers at the Forefront

The Evolution of Mixing Machinery: Horizontal Paddle Mixers at the Forefront Table of Contents 1. Introduction to Mixing Machinery 2. A Brief History of Mixing Machinery 3. Technological Advancements in Mixing Machinery 4. Understanding Horizontal Paddle Mixers 5. Applications of Horizontal Paddle Mixers 6. Advantages of Horizontal Paddle Mixers 7. The Future of Mixing Machinery 8

The Essential Guide to Horizontal Paddle Mixers: Applications and Benefits

Horizontal paddle mixers are vital components in various manufacturing and processing operations, particularly within the realm of mixing machinery. Understanding the workings and benefits of these mixers can significantly enhance operational efficiency and product quality. A horizontal paddle mixer typically features a cylindrical mixing chamber equipped with paddles that rotate on a horizontal a

Exploring the Dynamic Capabilities of Industrial Ribbon Mixers Table of Contents Introduction to Industrial Ribbon Mixers Understanding the Mechanics of Ribbon Mixers Advantages of Using Ribbon Mixers in Manufacturing Applications of Ribbon Mixers Across Industries Maintaining Your Ribbon Mixer for Longevity Future Trends in Ribbon Mixer Technology Case Studies: Ribbon Mixers in Act

Understanding Industrial Ribbon Mixers: Essential Tools for Effective Material Blending

Industrial ribbon mixers are vital pieces of equipment used in various manufacturing processes, particularly in the blending of powdered and granular materials. These mixers are characterized by their unique design, featuring a set of helical ribbons that move materials through the mixing chamber, ensuring a thorough and uniform blend. With increasing demands for consistency and quality in product