Focus: mixer installation problems!

The mixer is actually very easy to install. Under normal circumstances, the manufacturer will use water for trial operation in the factory. Customers only need to have three-phase 380V 50HZ electricity and air pressure. However, customers will still encounter some details during the installation process. Shanghai Neil Machinery will explain the installation details for you in detail:

Powder packaging machine manufacturers all kinds of packaging

Powder packaging is a product developed by human material civilization and energy civilization. The outer packaging of powder is the same as when people dress in diplomacy. Its function is very important. In addition to protecting powder, it can also facilitate transportation and storage. More importantly, it can promote the sale of powder and meet people's aesthetic needs. The numerous packages of powder packaging machine manufacturers show us a world of colorful colors.

Discussion on horizontal packaging machine

As far as the automatic packaging machine for domestic packaging products is concerned, it can be divided into three categories: vertical packaging machine, rotary packaging machine, and horizontal packaging machine. Today, let's talk about the horizontal packaging machine. Working principle of horizontal packaging machine The horizontal packaging machine is controlled by PLC to control the output of the frequency converter, so that the main motor drives the transmission shaft to rotate as required. The mechanical cam of the equipment on the transmission shaft converts the rotating motion into various linear motions. First, the roll-shaped packaging film is folded and formed, hot-pressed and sealed by a former into bags, and cut into independent bags by a cutter. After opening with a manipulator, the material is filled into the bottom of the bag, and then the opening is hot-pressed and sealed into products. All movements move in the horizontal direction, so it is also referred to as a horizontal machine.

Three common classifications of glove boxes

Three common classifications of glove boxes According to the use of the glove box is divided into three categories: 1. Inert gas glove operation box; 2. Isolate the glove box; 3. Anaerobic glove box.

Knowledge of vertical packaging machine

At present, many enterprises have introduced a variety of different packaging machines, and these different packaging machines can indeed play a very important role, while vertical packaging machines are what we often use. The characteristics and advantages of this packaging machine, related to other packaging machines, is also more significant, the first of this packaging machine can be suitable for use in different work and areas, that is, suitable for packaging materials, it is more extensive.

How to select and maintain packaging machine products

With the improvement of consumption level and the improvement of quality of life, the demand for some commodities has risen to a new level in pursuit of product appearance and quality. Therefore, it is necessary to make better decisions in terms of product diversification, versatility and personalization. In order to meet the needs of a wide range of consumers for various types of products, automatic packaging machinery and equipment must be improved and developed to produce various multifunctional automatic packaging machinery.

How to choose among the many packaging machine manufacturers on the market

There are many domestic packaging machine manufacturers. How to choose among the many packaging machine manufacturers on the market? Whether the vacuum packaging machine meets its own needs (packaging method, size, parameters, capacity, effect, etc.)

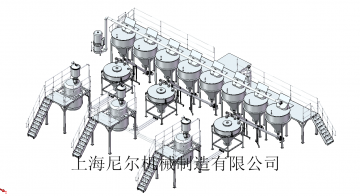

Coating automatic batching mixing production line built

After 16 days of installation, commissioning and testing, the Neil mechanical coating automatic batching and mixing production line was installed and commissioned at the customer's factory on December 12, 2019. The line is also suitable for processing other similar materials If you have similar needs, please feel free to contact us. Shanghai Neil Machinery supports any type of powder handling system customized according to different materials.

What is the role of power roller conveyor in the pharmaceutical industry

The application of power roller conveyor in modern industrial production is very common, usually in large production enterprises and small and medium-sized production enterprises can not be separated from the use of a variety of roller conveyor, so as to adapt to the bulk material, objects and various varieties of goods transport, and to meet the level, tilt and other transport line layout, so as to meet the diversified needs of enterprise production, and greatly improve the production efficiency of enterprises.